X-ray Shielding Materials

While we encourage you to utilise our expertise to provide a total radiation shielding package, we do recognise that in some circumstances the 'supply only' of these materials is more appropriate.

These materials are used within our own specialist products to provide effective shielding from:

- X-ray, Gamma & Neutron emissions

- Radio Frequency and Magnetic interference

- Creating a safe environment for patients, staff and members of the public.

We offer a fast and efficient service at competitive prices. Many items are held in stock for fast delivery times.

Table of Contents

Sheet Lead

Sheet Lead is available in a number of standard thicknesses from our extensive stocks. Non-standard thicknesses including lead plates are available to special order.

Milled to BS.1178 1969, the standard BS Codes and their respective weights are listed in the table on the right.

| British Standard Lead Thickness | ||

|---|---|---|

| BS Code | Thickness | Weight kg per m2 |

| Code 3 | 1.32mm | 15.00 |

| Code 4 | 1.80mm | 20.40 |

| Code 5 | 2.24mm | 25.40 |

| Code 6 | 2.65mm | 30.10 |

| Code 7 | 3.15mm | 35.70 |

| Code 8 | 3.55mm | 40.30 |

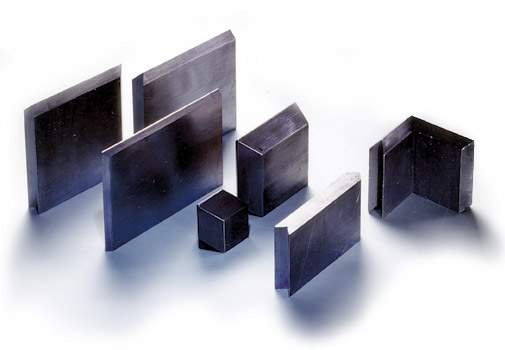

Lead Bricks

Where protection greater than 10mm is required, the use of interlocking lead chevron bricks is preferred.

Typical lead brick thicknesses are 10mm, 12mm, 15mm, 20mm and 25mm. For exceptionally heavy installations, laminations of bricks are used with the joints staggered.

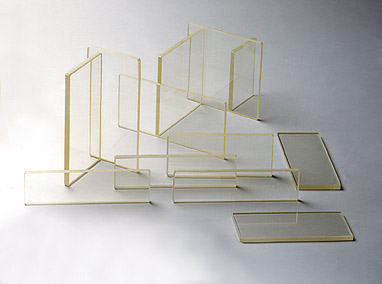

X-ray Glass

We are a leading distributor for Corning® Med-X® and Med-Gamma® glass for all types of radiation shielding involving X-ray and Gamma based PET radiation sources.

The production of Corning glass is strictly controlled and is manufactured in accordance with the Quality Standard ISO 9001, the Environmental Standard ISO 14001, and the Health & safety Standard OHSAS 18001.

Both types of lead glass can also be provided in sheet sizes up to 2800mm x 1400mm for wide fields of vision. However, please take into consideration the overall weights and handling implications of larger sheet sizes.

See Also

Corning® Med-X®

Corning® Med-X® Glass provides high quality, transparent and safe protective shielding against X-ray radiation for medical, technical and research applications.

Its high lead and barium content and wide range of thickness, provides optimum shielding from equipment operating in the 80 to 300kV range.

We carry large bulk stocks of X-ray shielded glass in sheet sizes 2000mm x 1000mm and four thicknesses which give lead equivalents from 1.5mmPb to 3.2mmPb @ 150kV. With our specially designed wall saw we are able to offer a fast ‘cut to order’ service.

Suitable for:

- Viewing windows for X-ray, angiography, and CT scans

- Screens for medical diagnostics

- Protection windows in laboratories

- Airport security X-ray screens.

| Corning® Med-X® | ||

|---|---|---|

| Physical Thickness | Lead Equivalent @ 150kV | Weight kg per m2 |

| 5/6.5mm | 1.5mmPb | 31.2kg |

| 7/8.5mm | 2.1mmPb | 40.8kg |

| 8.5/10mm | 2.6mmPb | 48kg |

| 11/13mm | 3.2mmPb | 62.4kg |

Corning® Med-Gamma®

Med-Gamma® is also available to special order, providing high quality, transparent and protective shielding from Gamma based radiation at various KeV levels.

It is manufactured in physical thicknesses from 7.0/8.5mm to 18/20mm providing respective lead equivalents 2.3mm to 5.9mm @ 511keV, although increased thicknesses (up to 45/53 mm, offering 15mm lead equivalent @ 511keV) can be achieved through lamination process using a 1.5mm interlayer.

Suitable for:

- Occupational protection from PET gamma radiation used in scanning techniques for diagnostics and treatment

- Cyclotron maintenance

| Corning® Med-Gamma® | ||

|---|---|---|

| Physical Thickness | Lead Equivalent @ 511keV | Weight kg per m2 |

| 7/8.5mm | 2.3mmPb | 40.8kg |

| 8.5/10mm | 2.8mmPb | 48kg |

| 14/16mm | 4.6mmPb | 76.8kg |

| 28/32mm | 9.3mmPb | 153.6kg |

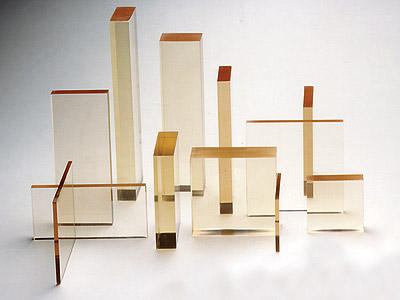

Premac® Lead Acrylic

Premac® lead acrylic is a lead loaded acrylic copolymer resin with particular shielding properties and can be used in the production of glove boxes, windows, mammography screens, laboratory ware, cabinets and bench shields.

The material is transparent with a very light brown tint, exhibiting virtually all the normal chemical and physical properties of conventional acrylic. The lead content is 30% wt/wt and is chemically introduced into the acrylic resin as an organolead salt.

Thickness and Lead Equivalence

It is available in a range of seven standard thicknesses (H8 to H70) and lead equivalents. We carry large stocks of the most popular sizes for fast delivery at competitive prices.

| Premac® Lead Acrylic | ||||

|---|---|---|---|---|

| Type | Physical Thickness | Lead Equivalent[1] | Weight kg per m2 | Maximum Dimensions (mm) |

| H8 | 8.5mm ±0.7mm | 0.3mm | 14kg | 1830 x 2440 |

| H12 | 12mm ±1mm | 0.5mm | 19kg | 1830 x 2440 |

| H18 | 18mm ±1mm | 0.8mm | 29kg | 1830 x 2440 |

| H22 | 22mm ±2mm | 1.1mm | 35kg | 1830 x 2440 |

| H35 | 35mm ±2mm | 1.5mm | 56kg | 1830 x 2440 |

| H46 | 46mm ±3mm | 2.2mm | 74kg | 1220 x 2440 |

Physical Properties

Premac® can be shaped and drilled to suit exact requirements and has a polished finish. We supply it with a special masking paper for protection during storage and handling.

Supplied in seven thicknesses and in sizes cut to special order, the material may be laminated to increase the shielding capabilities or bonded between sheets of plain acrylic.

| Physical Properties | |

|---|---|

| Density | 1.6 g/cm3 |

| Tensile Strength | 490 kg/cm2 |

| Elongation | 18% |

| Izod Impact Strength (notched) | 3.0 kg/cm2 |

| Refractive index nd | 1.54 |

| Reflective index p | 0.0454 |

Radiation Resistance

Premac® exhibits good radiation resistance. When exposed to a 1x105 total dose of Cobalt 60 gamma radiation little or no deterioration of its physical properties was observed as shown in the table below. In the same test the rate of discolouration forPremac® was also much less than for either lead or plate glass.

| Radiation Resistance | |||

|---|---|---|---|

| Dose (150 r/hr) | 1x104 | 5x104 | 1x105 |

| Retained flexural Strength (%) | 100 | 105 | 105 |

| Retained Izod Impact Strength (%) | 98 | 97 | 93 |

Chemical Resistance

Premac® has similar chemical resistance to conventional acrylic. This chart illustrates the chemical resistance, as judged by visual observation, of small samples immersed at 20°C for 1 week in the chemicals listed.

| Unsatisfactory Decomposed or dissolved | Some Attack Slight crazing or swelling | Satisfactory No effect |

|---|---|---|

| Acetic Acid (99%) Sulphuric Acid (98%) | Acetone Chloroform Meta-Cresol Diethyl Ether Dimethyl Formamide Ethyl Acetate Ethyl Alcohol (99.5%) Ethyl Alcohol (50%) Hydrochloric Acid (36%) Methyl Alcohol Methylene Dichloride Methyl Ethyl Ketone Nitric Acid (60%) Nitric Acid (12%) Pyridine Sodium Hydroxide (35%) Tetraline Tetrahydrofurane Toluene | Carbon Tetrachloride Dibutyl Phthalate Dioctyl Phthalate n-Hexane Isopropyl Alcohol Sodium Hydroxide (10%) Water |

Concrete Blocks

Our new QuantaShield™ Concrete Blocks are a versatile radiation shielding solution against X-rays, gamma rays, protons, neutrons and magnetic fringe fields.

The interlocking blocks are designed to minimise radiation leakage. They are easy to install, being sized for easy manual handling and stacking. They don't require any bonding agents reducing the need for wet trades on site.

They are manufactured in the UK from concrete with naturally recycled constituents and are available in densities between 2g/cc and 4g/cc. At higher densities they offer significant floor space saving compared with standard density concrete blocks on the market.

Customers are invited to discuss their project requirements and review the test room constructed from QuantaShield™ blocks at Wardray's factory in Brighouse, West Yorkshire. Please contact us for further information.